Future-proof solutions for public spaces

GreenMax offers a full package specifically for the design of the planting area and the protection of infrastructure in our environment.

Discover our future-proof, innovative and circular solutions for the public space.

The solutions of GreenMax

For a green living environment

- Root Protection & Guidance

- Tree Anchoring

- Aeration & Irrigation

- Trunk Protection

- Tree Pit Design

- Exterior Design

- Additional Solutions

ROOT PROTECTION & GUIDANCE

Prevent root disturbance with root protection and guidance. Root protection and guidance direct tree roots in the right direction during growth.

VIEW MORETREE ANCHORING

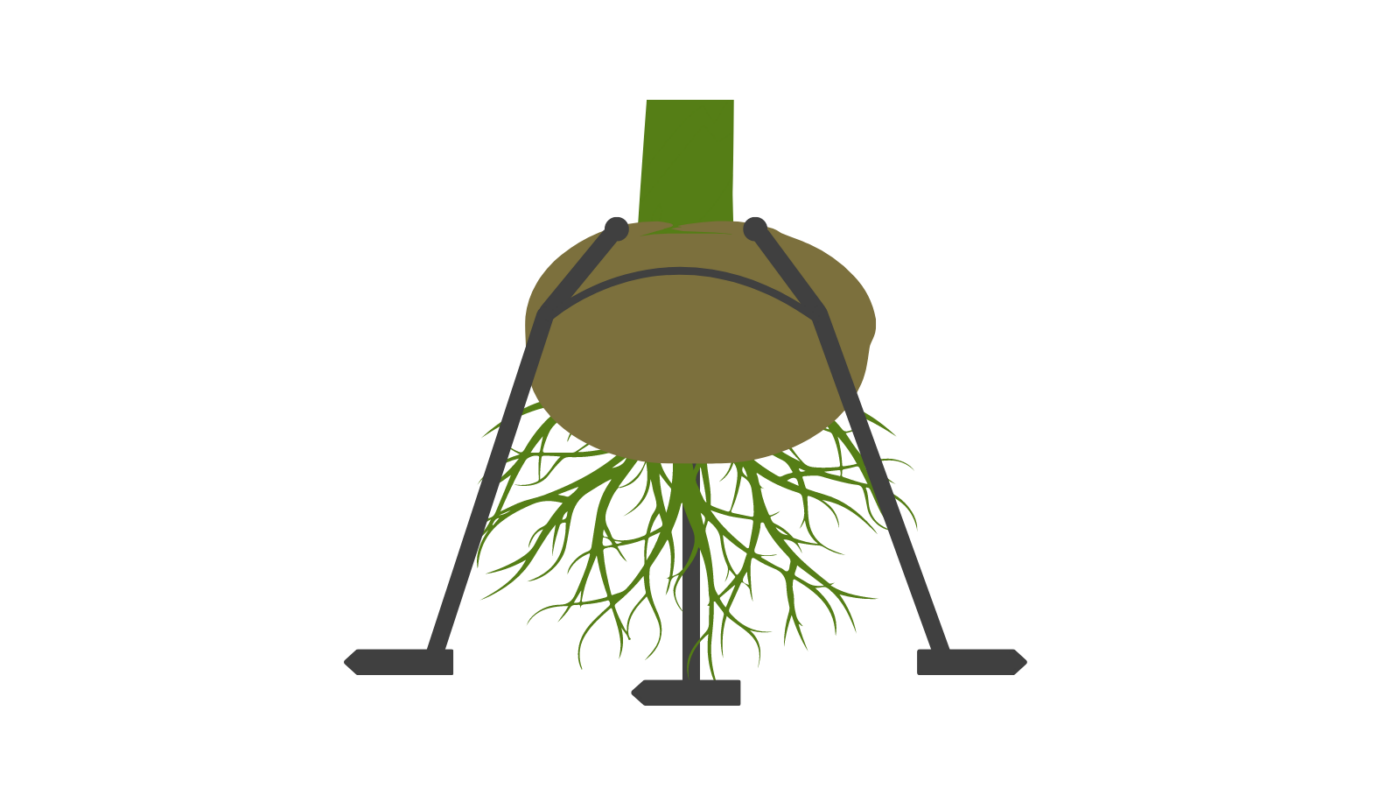

Prevent problems with staking and burial with young plantings with tree anchoring. Tree anchoring is important to ensure the stability of a tree during the first years of its growth.

VIEW MOREAERATION & IRRIGATION

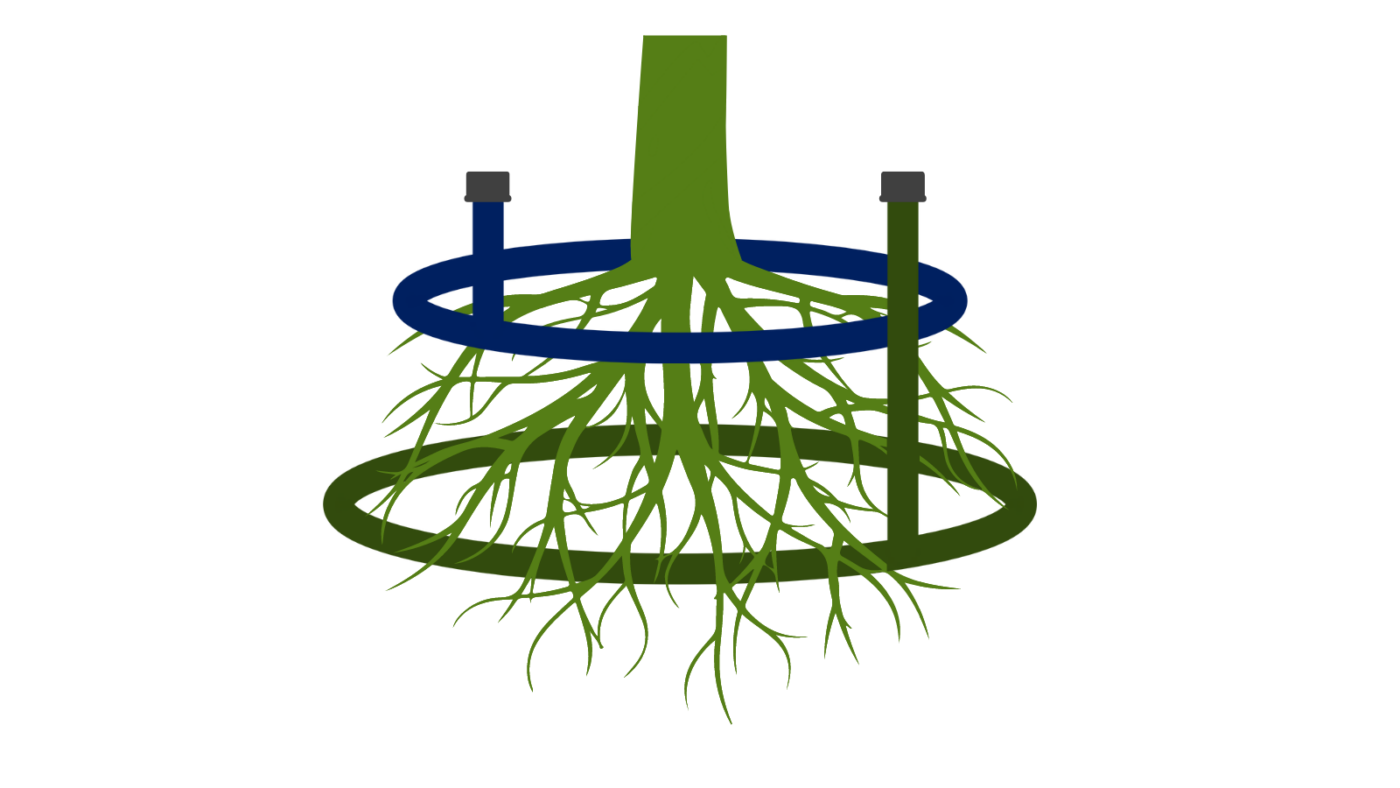

Many (young) trees, shrubs and hedges in the urban environment suffer from drought or lack of oxygen. Prevent problems with staking and burial with trees with our aeration and irrigation systems.

VIEW MORETRUNK PROTECTION

External influences, such as wildlife, mowing, excessive exposure to sunlight, frost and salt for icy roads, can cause damage to the trunk. GreenMax offers various solutions for the protection of the vulnerable tree trunk.

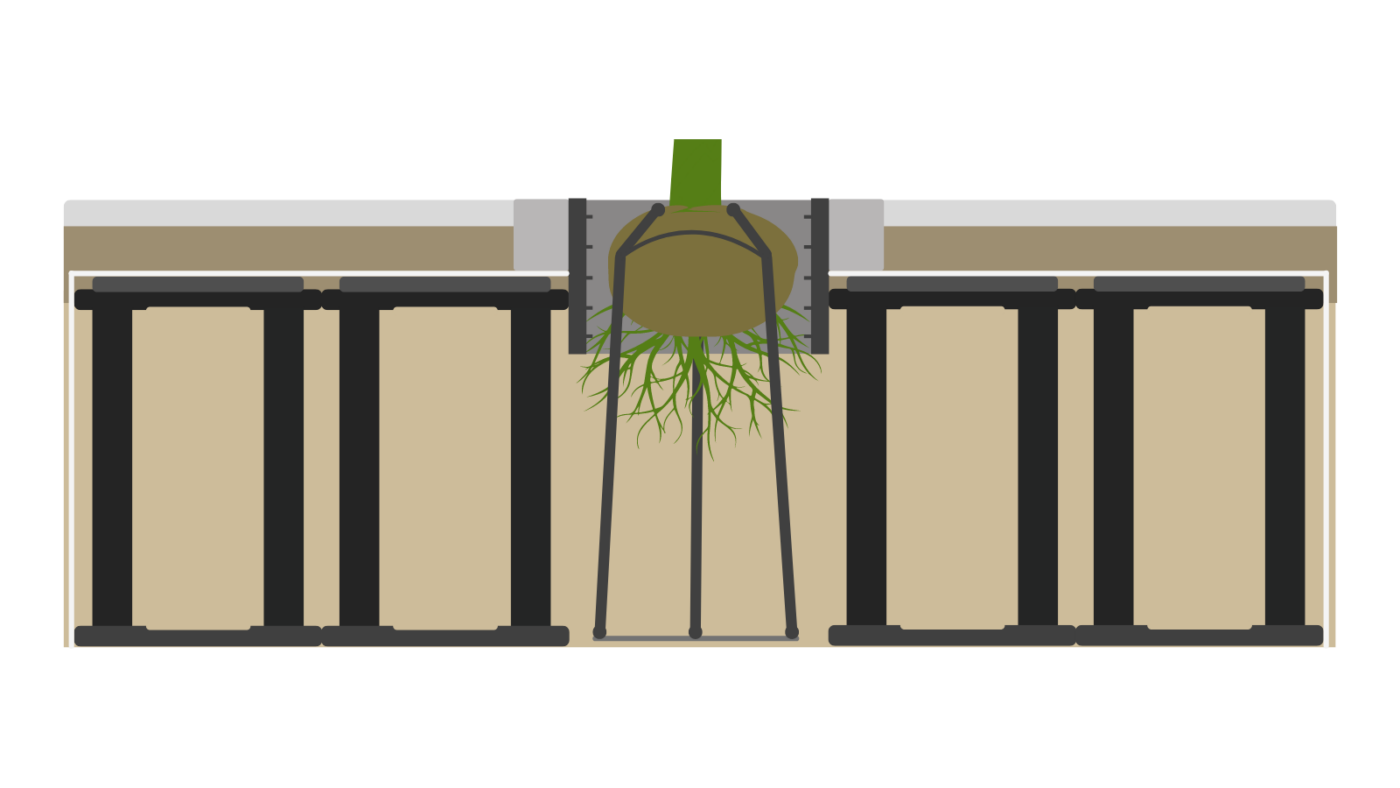

VIEW MOREHARD LANDSCAPING

Effective tools are crucial for trees to grow into large, healthy, mature and functional trees. Effective urban tree planting systems address all the problems associated with planting trees in the urban environment.

VIEW MOREEXTERIOR DESIGN

Green is good, green is healthy, green is beautiful. Green is necessary for the urban environment. With exterior landscaping you optimise urban green projects and create an attractive appearance in the public space.

VIEW MOREADDITIONAL SOLUTIONS

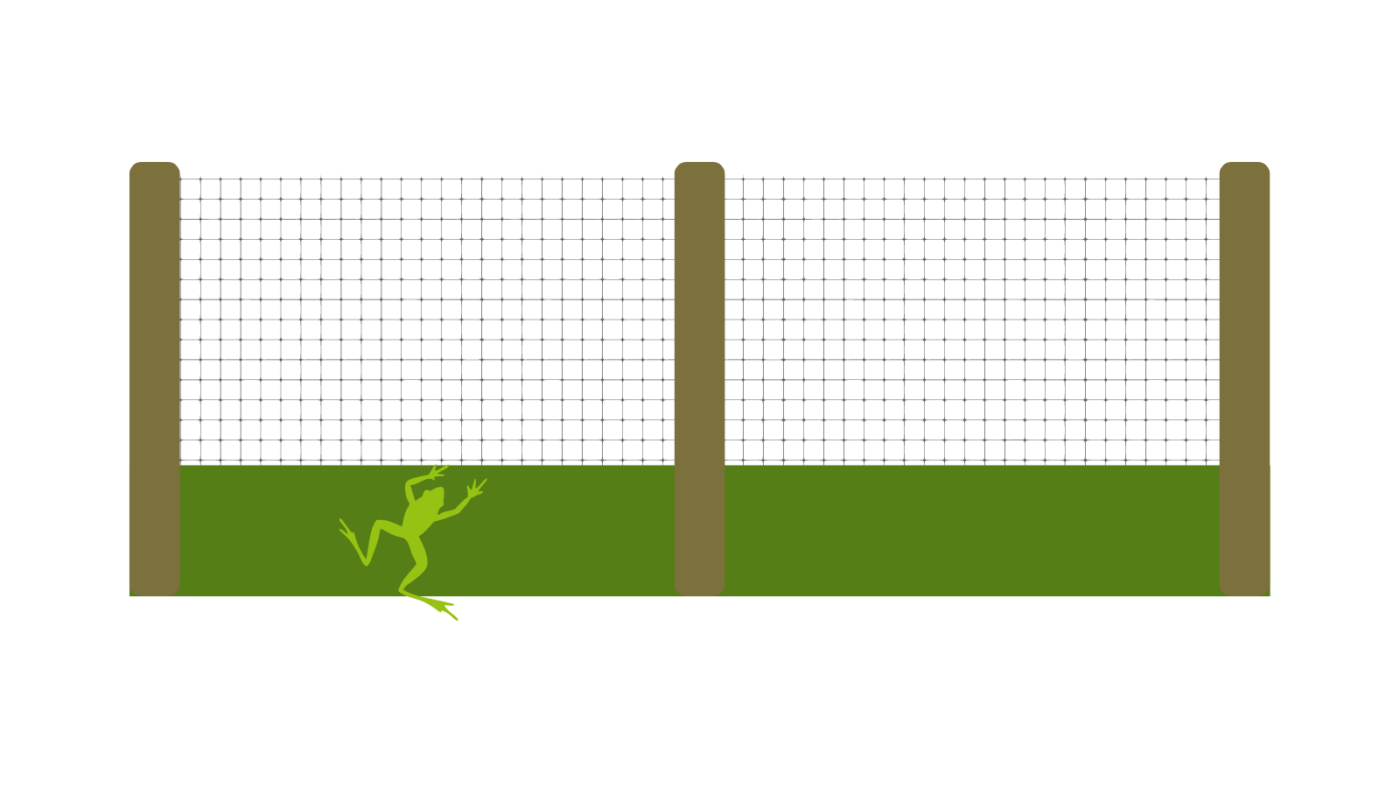

GreenMax offers additional solutions, such as amphibian screens, weed guards and gutter grids, for various applications.